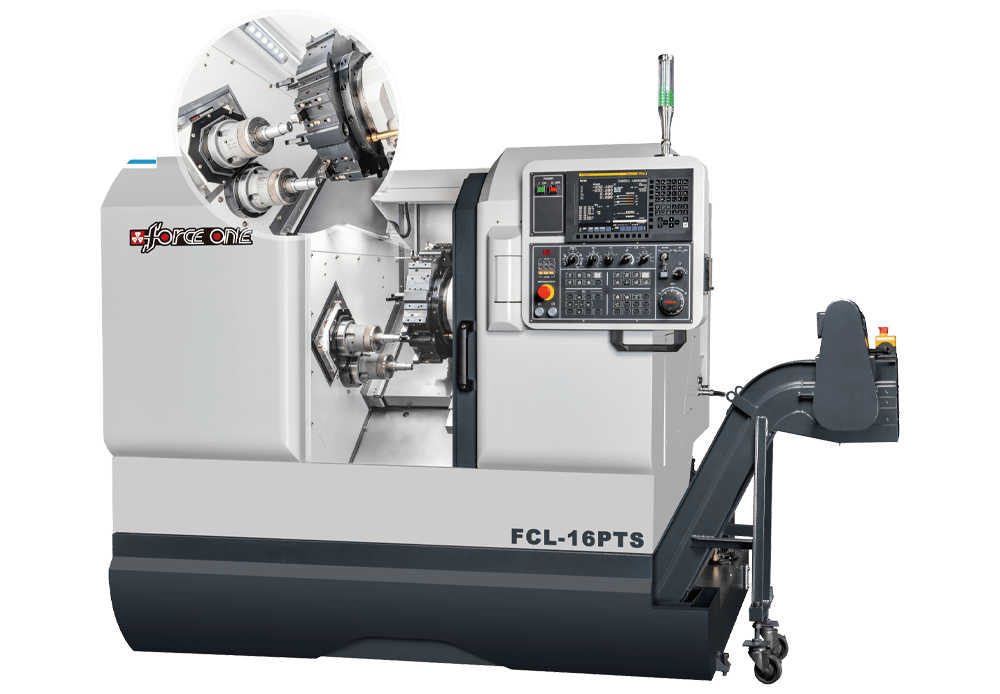

Swiss-Type CNC lathes are designed for ultra-precision machining of small and intricate parts, making them ideal for medical, electronics, and aerospace industries. Force One Machinery’s Swiss-Type CNC lathes feature synchronized twin spindles and multiple tool positions, enabling continuous high-precision machining with exceptional stability and consistency. Equipped with high-rigidity linear guides and precision feed systems, our machines maintain micron-level tolerance accuracy. With smart monitoring technology, spindle loads are automatically adjusted to ensure optimal cutting conditions. Offering high efficiency, precision, and stability, our Swiss-Type CNC lathes are the perfect solution for precision manufacturing industries."

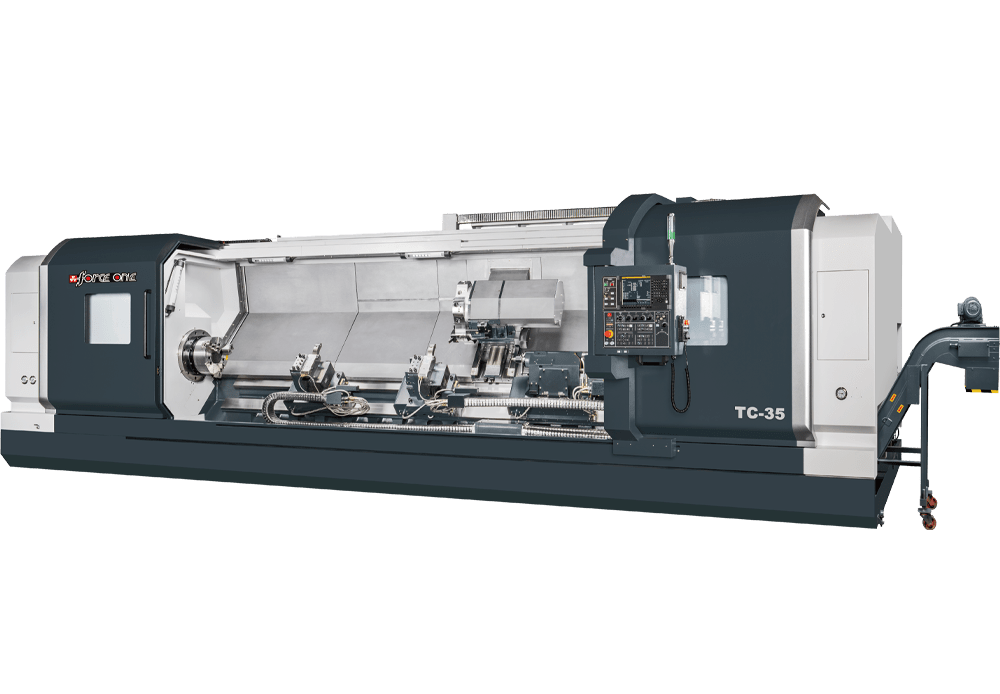

Force One Machinery specializes in multi-function CNC lathe technology, offering a diverse range of Swiss-type CNC lathes, twin-spindle twin-turret CNC lathes, advanced 5-axis turn-mill machining centers, heavy-duty oil country lathes, and large flat-bed CNC lathes. Our machines integrate high-rigidity structures, smart monitoring systems, and precision control technologies to ensure stable and efficient machining performance. With 5-axis simultaneous machining, ATC automatic tool changers, and synchronized twin-spindle technology, our solutions enable multi-process machining in a single setup, significantly improving productivity. Ideal for aerospace, automotive, energy, mold, and precision parts industries, Force One Machinery delivers flexible, high-precision turn-mill solutions to help businesses stay ahead in the market.

High-Precision CNC Lathes for Enhanced Stability & Efficiency