AUTOMATED PRODUCTION LINE (OPT.)

TWO AXES BAR FEEDER.

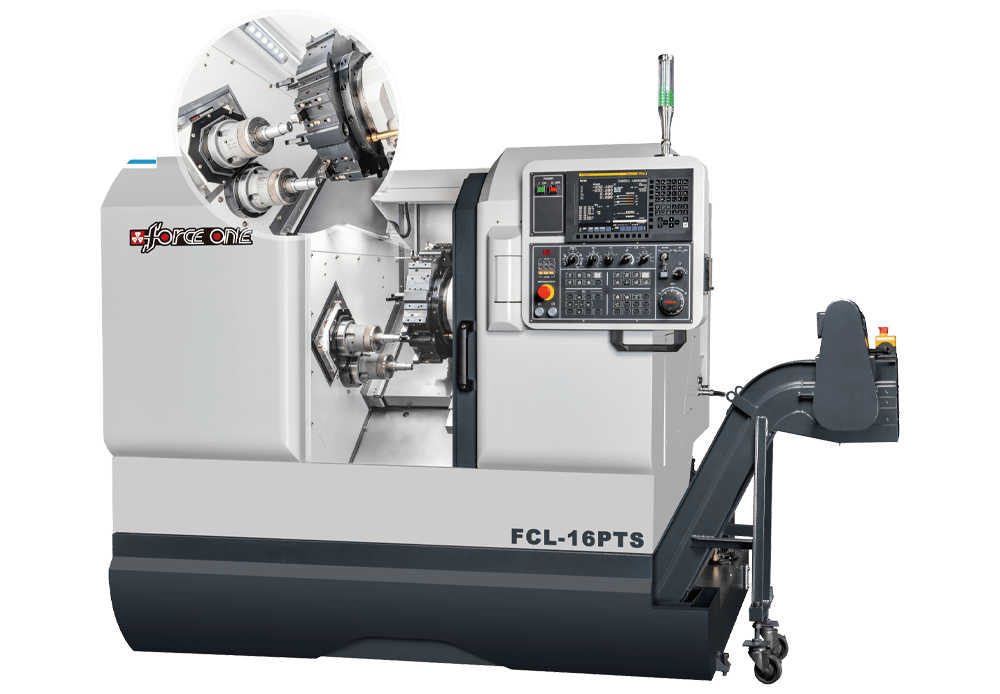

- The production process of the automated production line is as follows:

- The bar feeder with twin outfeeds delivers two bars into the parallel twin spindles of the turning center. After machining, the parts catcher will deliver the finished parts to the parts stocker.

- This production line can achieve two times the machining efficiency in the same area. occupation, low equipment investment costs, and low energy consumption.

BAR FEEDER WITH TWIN OUTFEEDS

GANTRY LOADER WITH MATERIAL MAGAZINE

Gantry Loader with Material Magazine

Gantry Loader with Outfeed Conveyor

2025. 02. 20

2025. 02. 20

Prev

Prev