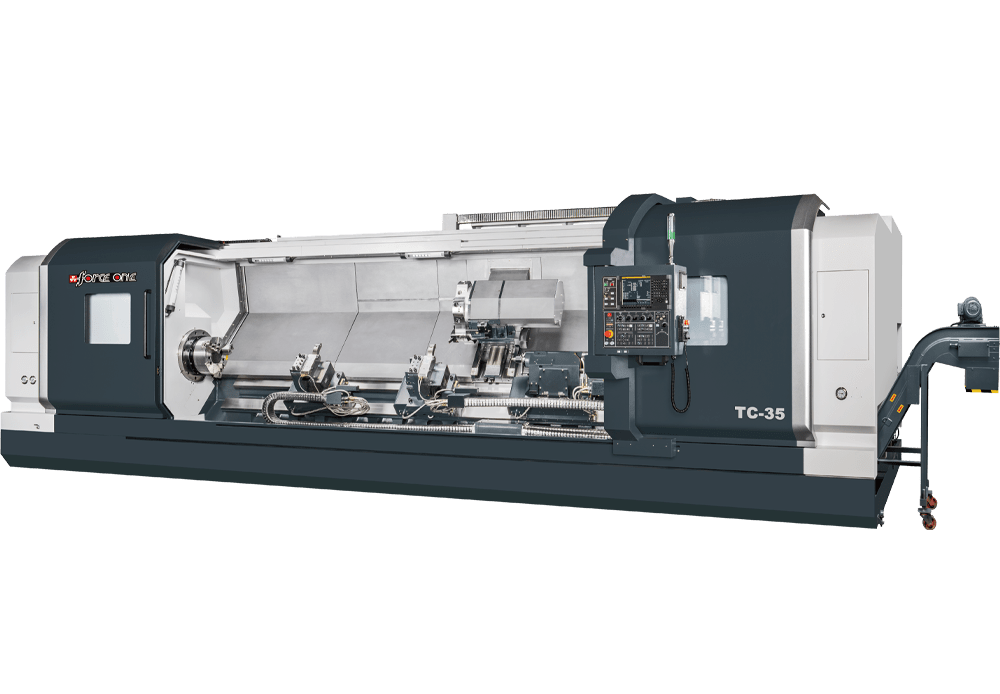

| Swing over bed | Ø 850 mm ( 33.45” ) |

| Swing over saddle | Ø 660 mm ( 226” ) |

| Max turning diameter | Ø 710 mm ( 27.95” ) |

| Working length | 760 mm ( 29.92" ) Opt: 1520 mm ( 59.8" ) / 2280 mm ( 89.76" ) / 3040 mm ( 119.688" ) / 4040 mm (159.05") / 5040 mm (198.42") / 6040 mm (237.79") |

| Spindle nose | Std : A2 - 8 / Opt : A2 - 11 / A2-15 |

| Bar capacity | Std: φ 89 mm ( 3.5” ) / Opt: A2-11:Ø117 mm ( 4.6 "), Ø142 mm ( 5.6" )/ A2-15: Ø166 mm ( 6.53" ) |

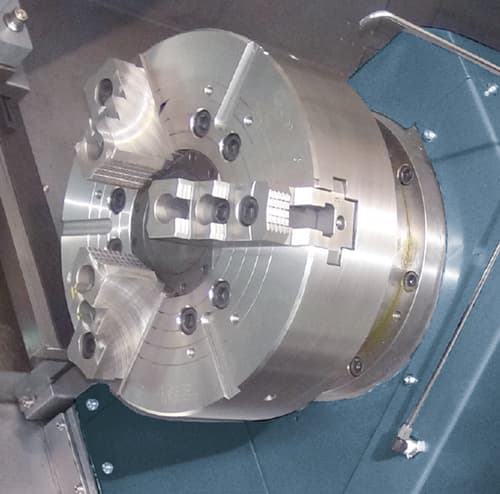

| Hydraulic chuck | Std: φ 304 mm ( 12” ) / Opt: φ 381 mm ( 15” ), φ 457 mm ( 18” ) |

| X axis travel | 355 mm + 25 ( 13.97 + 1” ) |

| Z axis travel | 860 mm (33.85") / 1620 mm (63.78") / 2380 mm (97.7") / 3140 mm (123.62") / 4140 mm (163") / 5140 mm (202.36") / 6140 mm(241.73") |

BMT TYPE OPT. The drawing will be provided by the requirement.

- All specifications, designs, and characteristics shown on this catalog are subject to change without prior notice.

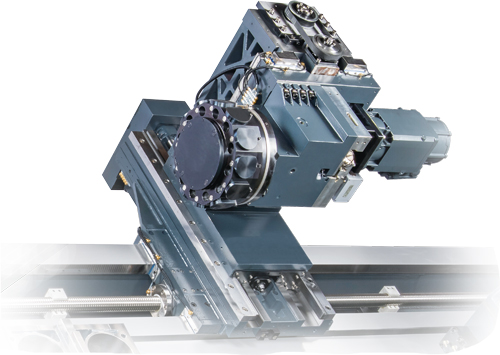

MACHINE FEATURE Y AXIS TURRET (OPT.)

- One-piece design of the Y-axis base and X saddle for high-accuracy structure configuration.

- Fast indexing turret features with high repeat accuracy.

- The high rigidity turret is better for front and back machining.

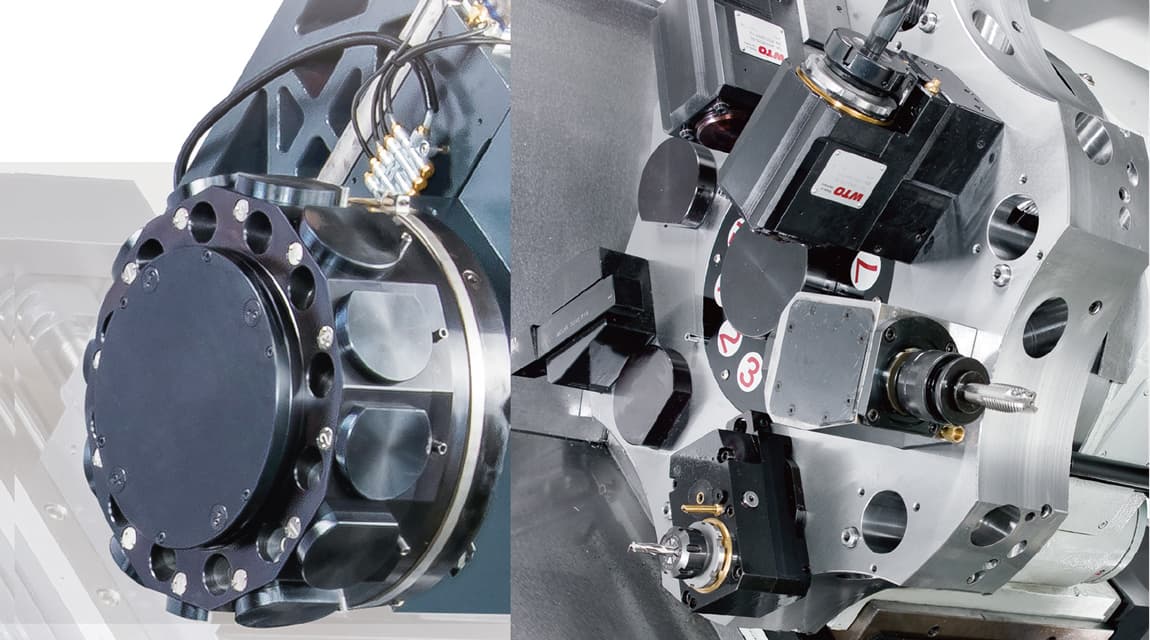

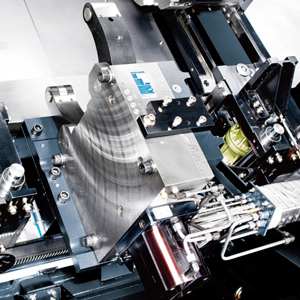

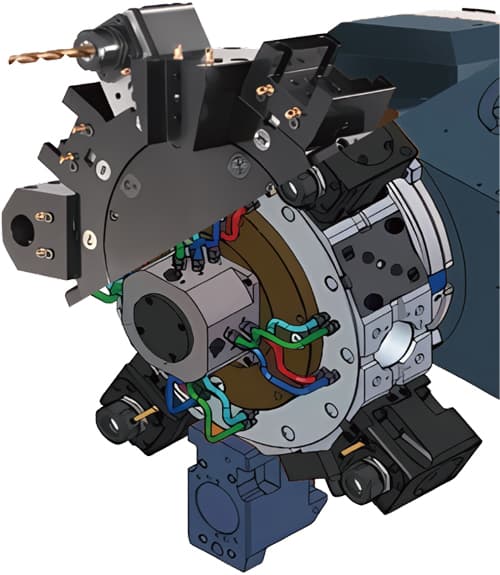

POWER TURRET (OPT.)

- Employs VDI 50 axial turret disk, 12 position power turret. (Two PCD Inner PCD has 6 stations for milling. Outer PCD has 6 stations for turning )

- High indexing resolution for contour/index control.

- Hydraulic disk brake locking provides maximum stability during milling and contouring.

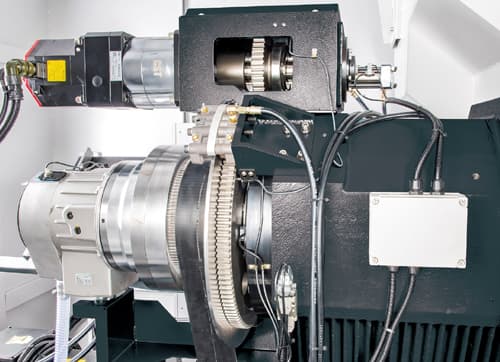

CF AXIS (OPT.)

CF axis with additional servo motor and gearbox. it has better rigidity for simulation milling.

CF AXIS (OPT.)

CS axis is driven by a servo spindle motor, it is suitable for spindle indexing and milling at position.

REAR CHUCK (OPT.)

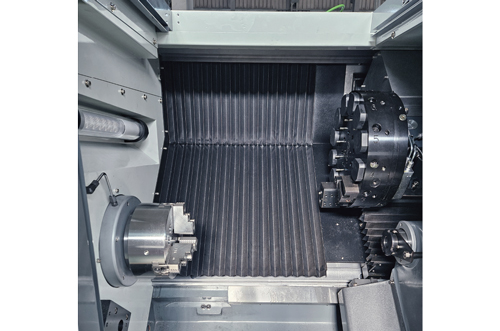

THE TELESCOPIC RUBBER

COVER (OPT.)

Provides superior micro-dust protection for the track and extends the lifespan of the cover during composite material grinding operations.

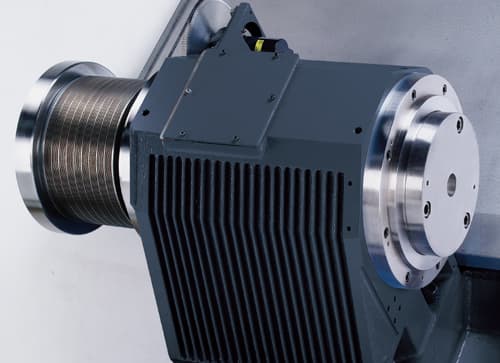

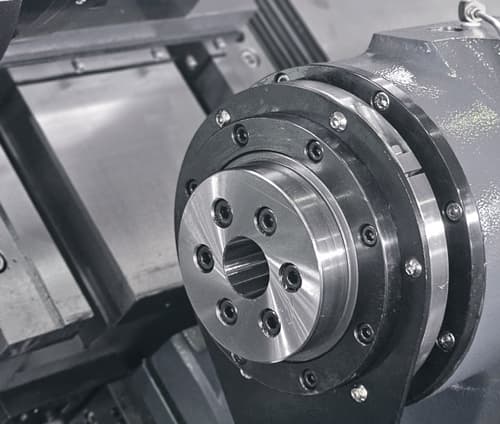

POWERFUL HIGH-SPEED

AND HIGH-RIGID SPINDLE (TC-35/40 series)

The spindle supported by cylindrical roller bearings and high-speed angular thrust bearings marks the spindle as faultless and ideal for heavy duty and high-speed turning.

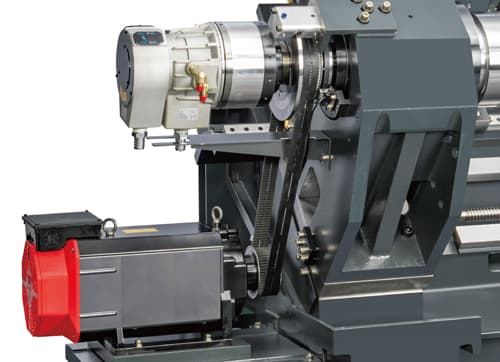

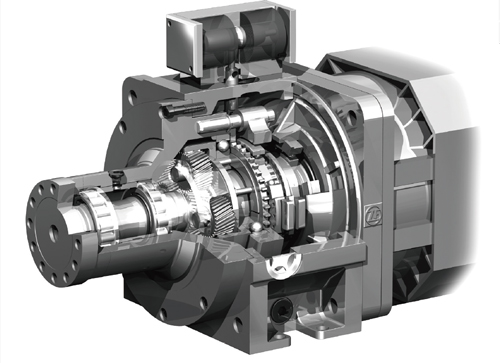

2-STAGE SPEED GEAR BOX

(TC-35/40 series)

The TC-35/TC-40 series is equipped with a "high precision" stages gearbox (Gear ratio 1:4) that provides full horsepower cutting from 208~2,500 rpm. The maximum cutting torque is 660 NM.

GEAR BOX (TC-45/50 series)

The headstock is with a 3 or 4-speed gear head, Gears are precision-ground for quiet running.

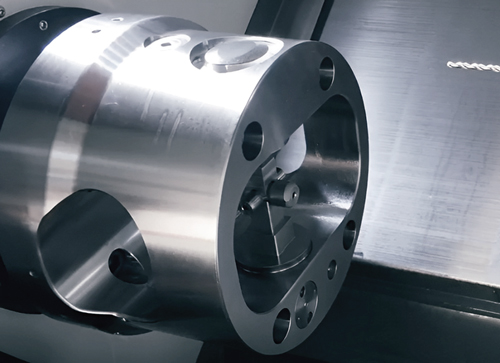

INDEX CHUCK(OPT.)

Capable of turning multi-angle machining parts, such as tees and crosses, with automatic angle adjustment and complete processing at one time.

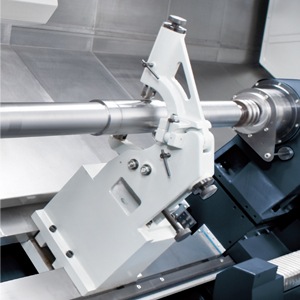

STEADY REST (OPT.)

The manual steady rest/hydraulic power unit offers a further level of customization, allowing the incorporation of a temporary toolpost and servo-driven movement functionality (To be used in conjunction with the toolpost) to meet the specific machining requirements of our customers.

WORKPIECE PROBE

TOOL MEASURE SYSTEM

Manual / Automatic swing arm.

WORKPIECE MEASURE SYSTEM

Automatic measurement and correction of dimensions.

SPINDLE COOLER (OPT.)

The spindle cooler is designed for high-precision machining, ensuring stable temperature control to prevent overheating, which can compromise accuracy and cause equipment wear. Its efficient cooling system enhances machining stability, extends spindle lifespan, and improves productivity and product quality, making it an essential component for reliable machine operation.

SUB SPINDLE (OPT.)

Synchronization for main and sub-spindle. The workpiece can be machined at one time,

ESG (OPT.)

AUTOMATIC GREASE LUBRICATION SYSTEM

It significantly reduces lubricant usage, effectively reduces coolant tank pollution, and improves coolant quality.

VARIABLE FREQUENCY HYDRAULIC SYSTEM

Excellent energy-saving effect, smaller fuel tank volume, and temperature control.

SMART POWER-OFF SYSTEM

A smart power-off system temporarily limits the use of power-hungry devices during standby. After processing is completed, the system can automatically power off the equipment.

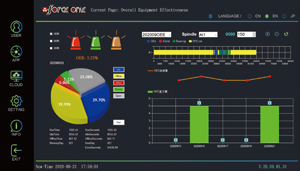

SMART MACHINE MONITORING AND PREVENTION SYSTEM (OPT.)

Real-time spindle load monitoring is combined with artificial intelligence software technology to automatically construct a safe processing load zone, and includes intelligent tool performance management to monitor and prevent abnormalities during processing, eliminating the need for human supervision.

BMT & AUTO TOOL CHANGE TURRET SOLUTION (OPT.)

The BMT interface turret features a more rigid structure, supporting a wide range of live tooling options and quick-change interfaces, such as Capto, enabling efficient external tool management. Additionally, we offer a hydraulic turret auto-change solution, which, when combined with a robotic arm, enables automated turret tool-changing functionality.

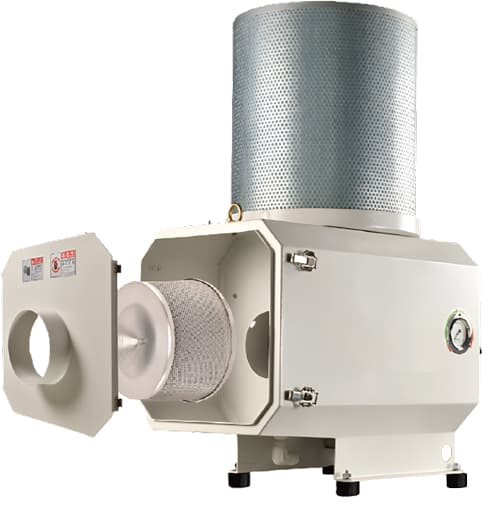

DUST COLLECTOR (OPT.)

The dust collector is designed for efficient dust management, swiftly capturing fine particles and debris during machining to maintain a clean workspace, enhance machining accuracy, and improve operational safety. Its advanced filtration system ensures that discharged air meets environmental standards, while also extending equipment lifespan, making it an ideal solution for maintaining a productive environment.

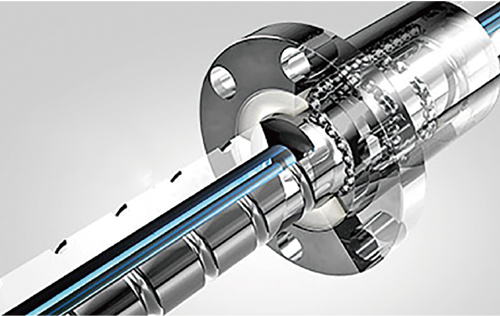

HOLLOW BALL SCREWS WITH COOLANT SYSTEM (OPT.)

The hollow ball screw cooling system can significantly reduce the thermal temperature rise position accuracy error caused by screw friction during machine movement, thereby improving the positioning accuracy of the machine.

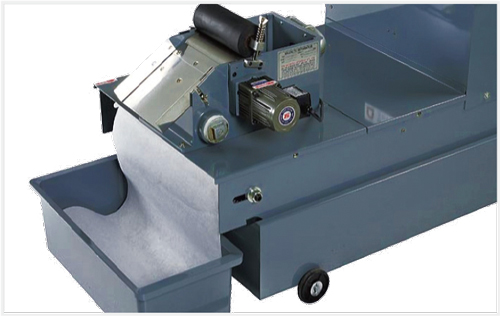

COOLANT CONTROL SYSTEM (OPT.)

- Hight pressure coolant system 5/10/20/50/70 bar

- Oil skinner

- Paper filter system

- Magnetic filter system

CONTROLLER

The standard controller is FANUC, there are other controllers such as SIEMENS, MITSUMISHI, FAGOR, SYNTEC, and others you could select as optional.

OIL MIST COLLECTOR (OPT.)

The oil mist collector uses advanced separation technology to efficiently capture oil mist generated during machining, reducing air pollution and improving workshop environment quality. Recovered cutting fluids can be recycled, saving costs and extending equipment lifespan, making it the perfect blend of environmental and economic benefits.

ROTATE QUILL TAILSTOCK (OPT.)

The higher rigidity rotated quill-type tailstock has bigger bearings than the live center.

2025. 02. 20

2025. 02. 20

Prev

Prev