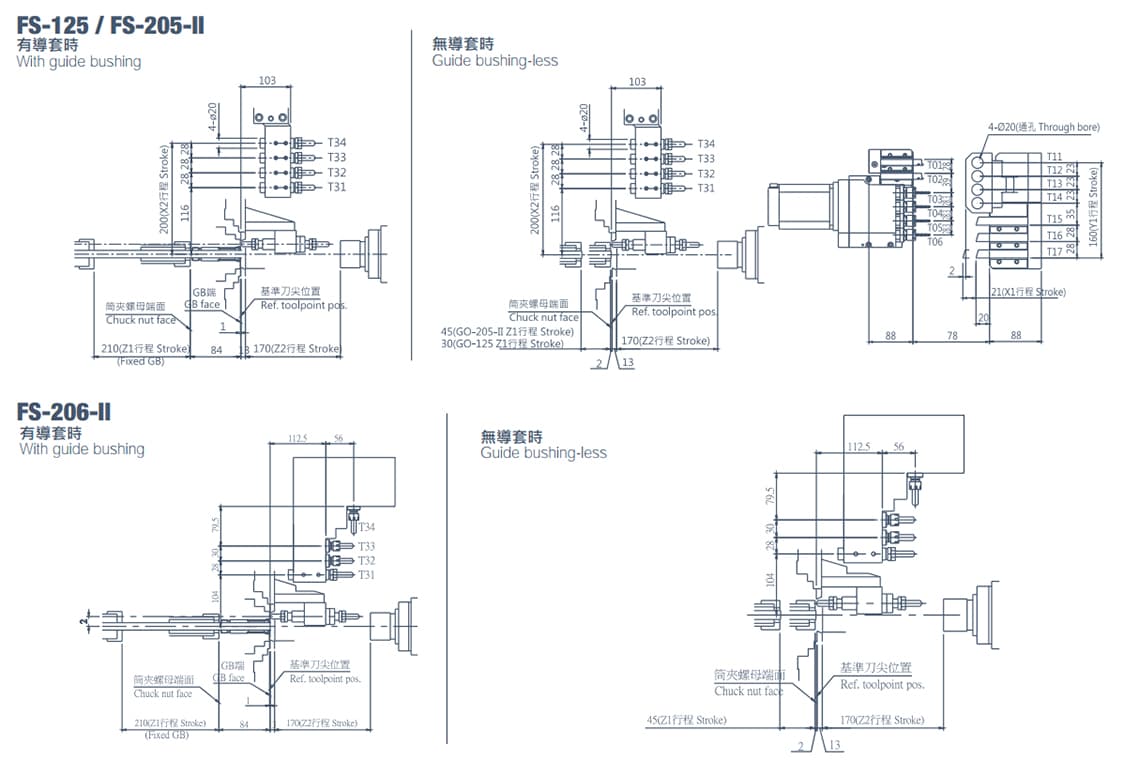

| ITEM | FS-206 | FS-207 |

|---|---|---|

| No. of tool positions | 28 | 31 |

| Max. No. of mountable tools | 39 | 35 |

| OD tool (T04 - T08,T21 -T23) | 8 | 8 |

| Face fixed ID tool (T15 - T19) | 5 | 4 |

| Face deep-hole drilling tool (T91 - T92) | 2 | 2 |

| Back fixed ID tool (T35 - T38, T45 - T29) | 4( OPT.: 9) | 4(OP.: 8) |

| Left cross live tool (T01 - T03) | 3 | 3 |

| Right cross live tool (T11 &T13) | 2 | 3( B-axis) |

| Face live tool (T11&T13) | 0( OPT.: 4) | 3( B-axis) |

| Back live tool (T31- T34, T11&T13) | 4( OPT.: 8) | 4 + 3( B-axis) |

2025. 02. 20

2025. 02. 20 Prev

Prev