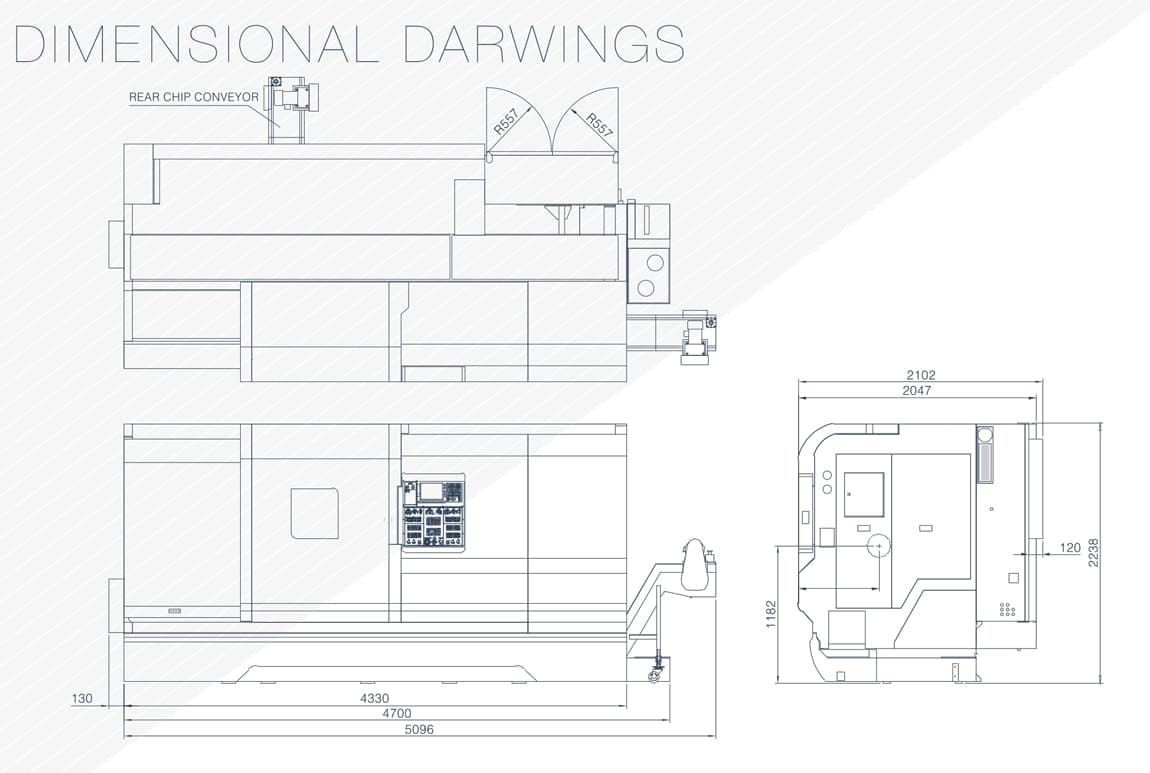

| Swing over bed | Ø 235 mm ( 9.25” ) |

| Max turning diameter | Ø 230 mm ( 9.06” ) |

| Working length | 690 mm ( 27.17” ) |

| Spindle nose | JIS: A2 - 5 / A2 - 6 (OPT.) |

| Bar capacity | Ø 52 mm ( 2.04” ) / OP: Ø 65 mm ( 2.55” ) |

| Hydraulic chuck | Ø 169 mm ( 6” ) / OP: Ø 210 mm ( 8” ) |

| X-axis travel | X1: 180 mm ( 7.09” ), X2: 185 mm ( 7.28” ) |

| Z-axis travel | Z1,Z2: 630 mm ( 24.8” ) |

-All specifications, designs, and characteristics shown on this catalog are subject to change without prior notice.

20 BAR HIGH PRESSURE COOLANT.

SYSTEM (OPT.)

The 20 bar high-pressure coolant system is recommended for high-production machining.The super high-pressure coolant at 70 bar can extend tool life and accelerate the turning feed rate, reducing insert costs and increasing production output.

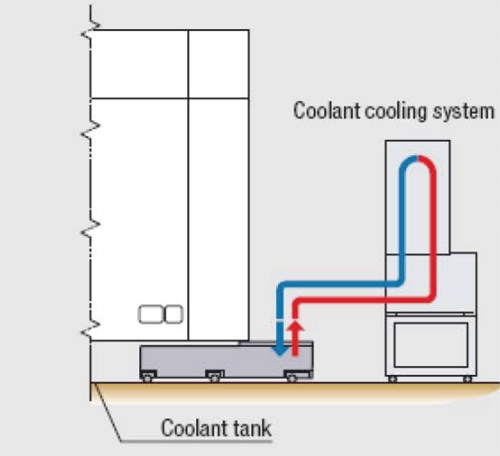

COOLANT CHILLER (OPT.)

The coolant chiller is used to control the temperature of coolant, helping to ensure consistent machining accuracy. The chiller is essential equipment when high-pressure coolant is used.

PARTS UNLOADER AND CONVEYOR

FOR SUB-SPINDLE (OPT.)

Once the workpiece is machined by the right spindle, it will be delivered to the parts unloader by the part ejector. Then the workpiece is discharged to the parts conveyor.

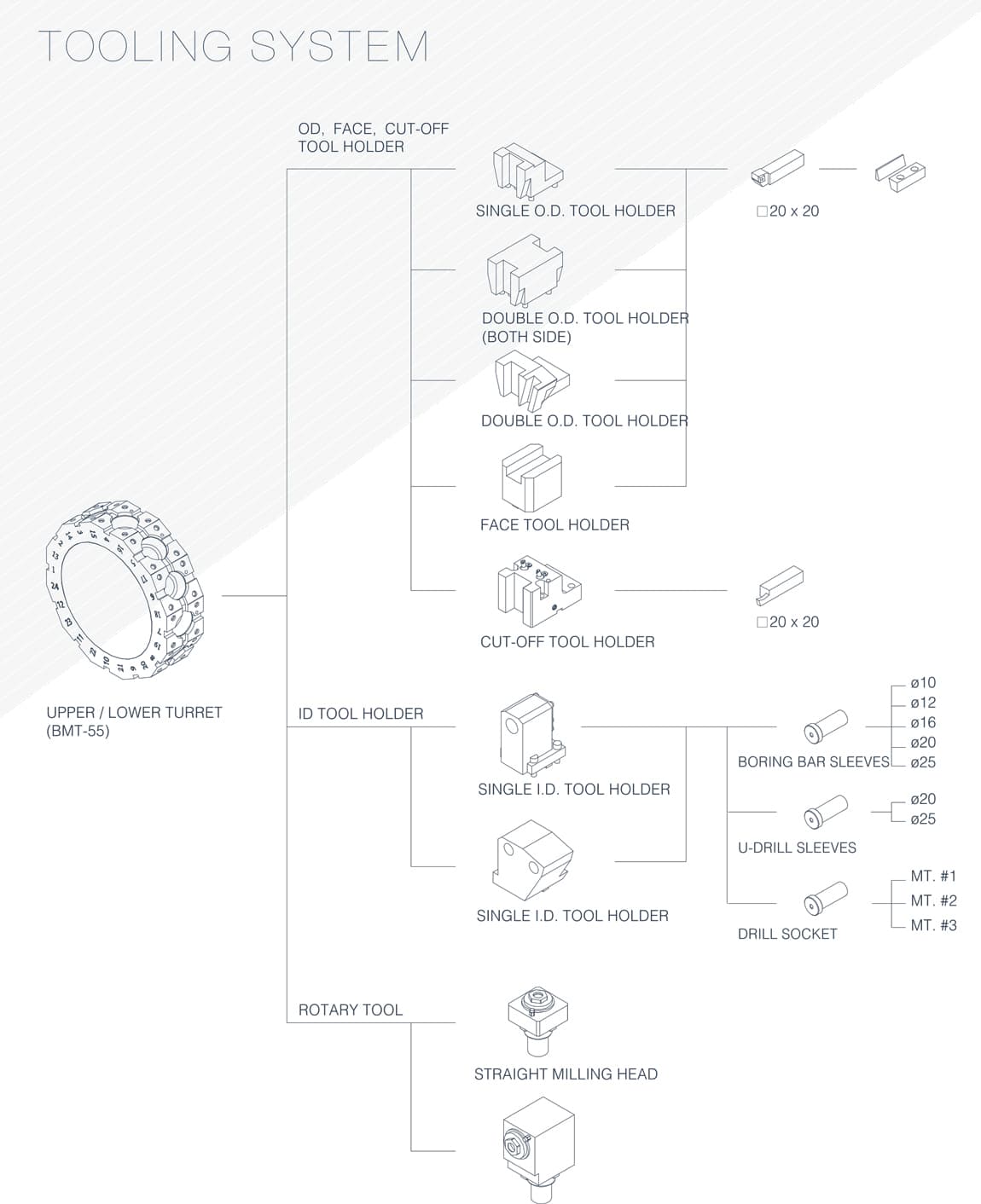

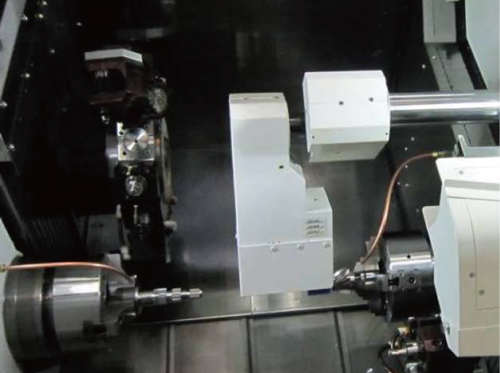

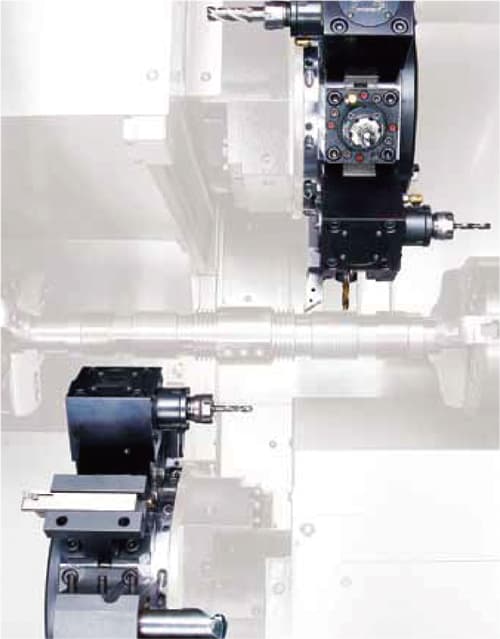

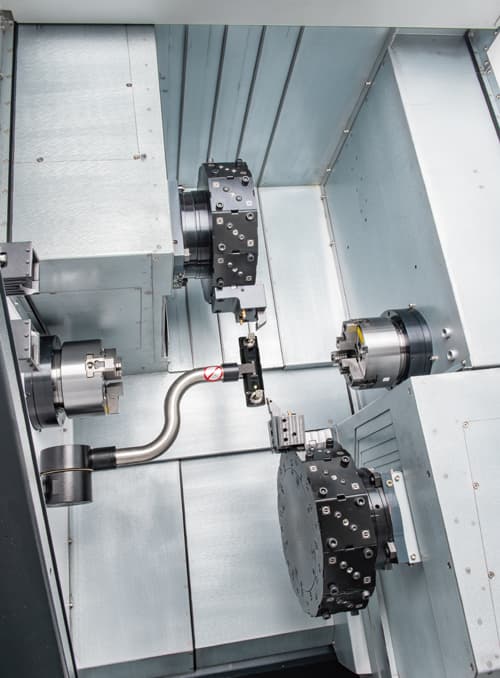

TURRET

The upper and lower turrets double machine productivity by allowing Independent, simultaneous operation.

- Turret indexing time (1 Face)

0.15s - No, of tool station

(The same for the upper and lower turrets)

12 station - No, of index positions

(The same for the upper and lower turrets)

24 index position

AUTO TYPE

TOOL PRESETTER (OPT.)

The CNC lathe tool measurement system enables automatic tool offset setting,significantly reducing manual tool calibration time. This not only enhances work efficiency but also greatly minimizes tool setup time during tool changes.

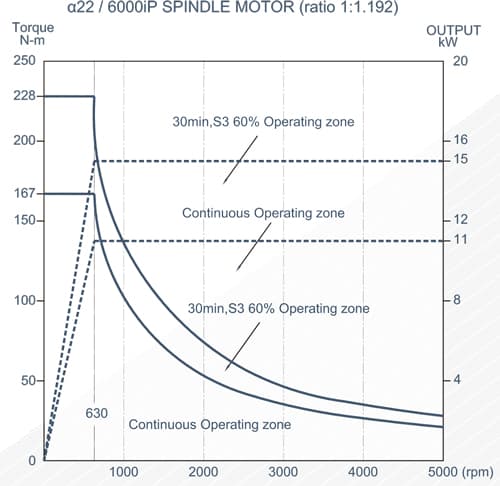

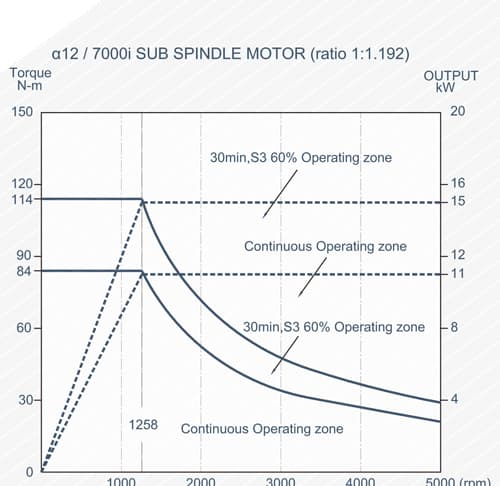

SPINDLE POWER - TORQUE DIAGRAM

- All specifications, designs, and characteristics shown on this catalog are subject to change without prior notice.

2025. 02. 20

2025. 02. 20

Prev

Prev